The Future of Manufacturing: Exploring China Rapid Prototyping

In today’s fast-paced industrial landscape, rapid prototyping has emerged as a crucial element for companies looking to innovate and bring new products to market efficiently. Among the foremost destinations for rapid prototyping is China, where a robust ecosystem of metal fabricators and advanced manufacturing technologies fuels creativity and transformation. This article delves into the essentials of China rapid prototyping, its advantages, applications, and how it is shaping the future of manufacturing.

Understanding Rapid Prototyping

Rapid prototyping refers to a suite of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. The aim of rapid prototyping is to accelerate the product development process, enabling designers and engineers to create tangible prototypes in a significantly shorter time frame than traditional methods allow.

Key Characteristics of Rapid Prototyping

- Speed: Rapid prototyping reduces the time from conception to production.

- Cost-effective: It minimizes material costs and reduces waste.

- Flexibility: Allows for easy modifications and iterations during the design process.

- Accuracy: High precision in creating prototypes that closely resemble the final product.

Why China is a Leader in Rapid Prototyping

China has positioned itself as a global leader in rapid prototyping for several compelling reasons. Understanding these can provide valuable insights into why businesses are increasingly turning to Chinese manufacturers for their prototyping needs.

Advanced Technology and Facilities

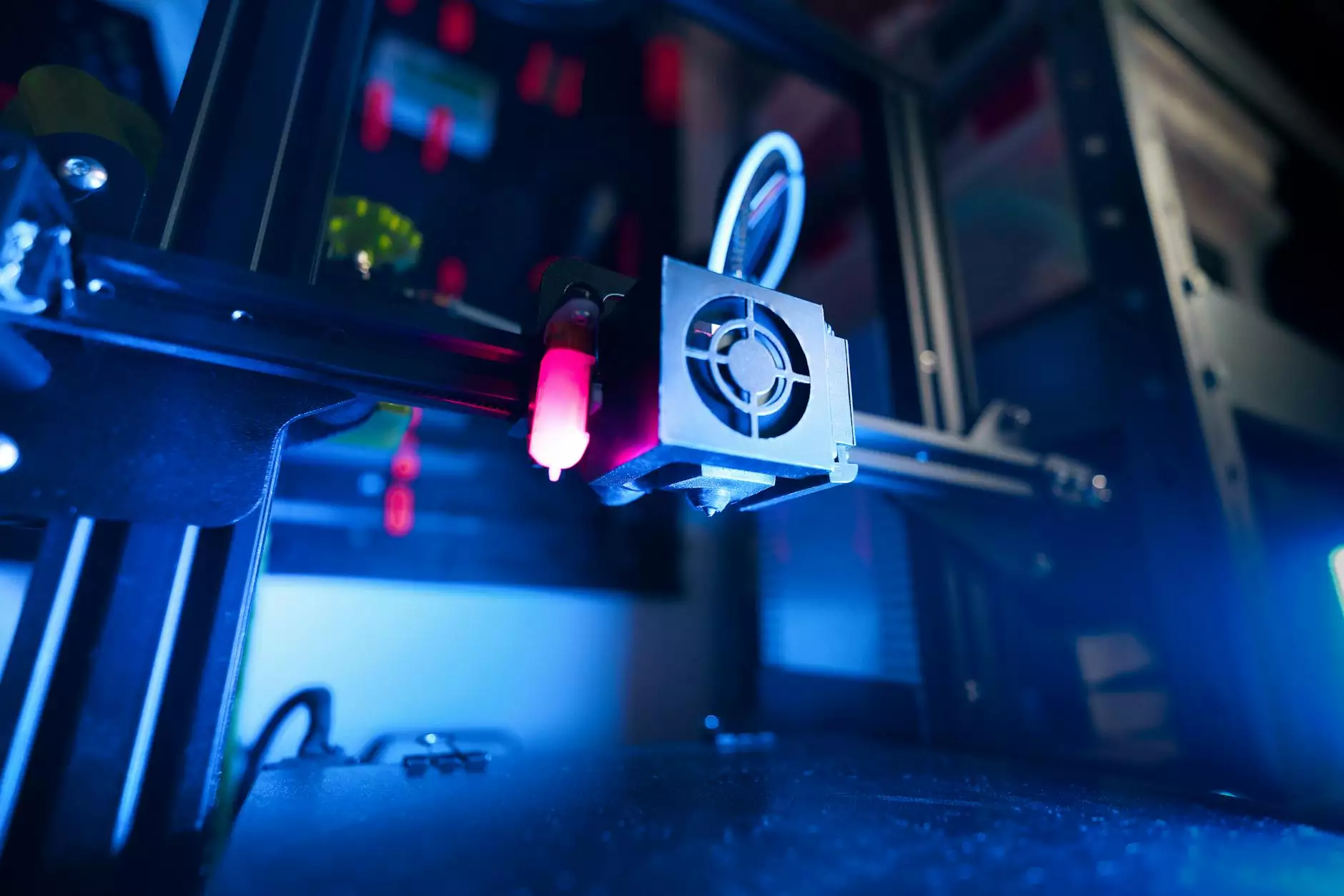

China hosts state-of-the-art manufacturing facilities equipped with the latest 3D printing and subtractive manufacturing technologies. These facilities are capable of producing intricate designs and utilizing a wide range of materials, including metals, plastics, and composites. The Chinese market has embraced innovation, continually integrating new technologies to enhance rapid prototyping capabilities.

Skilled Labor Force

With an extensive workforce experienced in engineering and manufacturing, China benefits from a pool of skilled labor dedicated to metal fabrication and prototyping. The expertise of the workforce allows companies to produce high-quality prototypes with impressive turnaround times.

Cost Efficiency

One of the most attractive aspects of China rapid prototyping is its cost-effectiveness. Lower labor costs, combined with competitive material pricing, enable companies to access high-quality prototypes without straining their budgets. This financial advantage is crucial, especially for small to medium-sized enterprises (SMEs) looking to innovate.

Applications of Rapid Prototyping in Different Industries

The versatility of rapid prototyping allows it to be applied across various industries, each benefiting uniquely from this technology. Below are some prominent sectors where rapid prototyping plays a significant role:

1. Automotive Industry

The automotive sector utilizes rapid prototyping to test new designs, components, and systems quickly. By creating functional prototypes, manufacturers can carry out rigorous testing and make necessary adjustments before mass production.

- Component Testing: Individual parts can be tested for fit and functionality.

- Design Validation: Designers can quickly iterate their designs based on feedback.

- Market Readiness: Prototypes help gauge consumer reactions before full-scale production.

2. Aerospace Industry

In aerospace, where safety and efficiency are paramount, rapid prototyping allows engineers to create lightweight, high-strength structures. Prototypes are vital in testing materials under various conditions to ensure that they meet rigorous standards.

- Material Testing: Prototypes facilitate the assessment of new materials.

- Complex Geometry: Allows for the creation of intricate designs that are lightweight.

3. Medical Devices

The medical device industry leverages rapid prototyping to develop instruments, implants, and prosthetics. Rapid prototyping helps in customizing products to individual patient needs, significantly improving the overall effectiveness of medical treatments.

- Customization: Tailoring devices to meet the unique requirements of patients.

- Testing and Evaluation: Facilitates the iterative process of testing for effectiveness and safety.

4. Consumer Products

From electronics to household items, consumer products are rapidly prototyped to meet market demands. Quick iterations allow companies to refine their designs, leading to enhanced user experience and satisfaction.

- Market Research: Prototypes can be used to gather customer feedback.

- Design Optimization: Enables companies to enhance product aesthetics and functionality.

How to Choose the Right China Rapid Prototyping Partner

Choosing the right partner for China rapid prototyping is crucial for the success of your project. Here are several factors to consider:

1. Expertise and Experience

Look for a metal fabricator with a proven track record in your industry. A partner with relevant experience will better understand your needs and deliver superior results.

2. Technology and Equipment

Evaluate the technology and machinery that your potential partner uses. Advanced technologies ensure higher precision and better quality in the prototypes produced.

3. Communication and Collaboration

Effective communication is key to a successful partnership. Choose a company that is responsive and willing to collaborate closely throughout the project.

4. Understanding of Regulations

Your partner should have a good understanding of various industry regulations pertaining to manufacturing and safety standards, especially in sectors like aerospace and medical devices.

The Advantages of Collaboration with Deep Mould

For businesses seeking reliable partners in rapid prototyping, Deep Mould stands out among the metal fabricators in China. Here’s why:

1. Comprehensive Services

Deep Mould offers a full suite of services for rapid prototyping, ensuring all your manufacturing needs are met under one roof. From design to production, clients benefit from seamless integration and streamlined processes.

2. Commitment to Quality

At Deep Mould, quality assurance is paramount. Every prototype undergoes rigorous testing and evaluation, ensuring that it meets the highest industry standards.

3. Customer-Centric Approach

The team at Deep Mould prioritizes customer satisfaction, collaborating closely with clients to align with their vision and objectives. This approach leads to successful outcomes and long-term partnerships.

The Future of Rapid Prototyping in China

As the industry continues to evolve, the future of China rapid prototyping looks promising. Emerging technologies such as AI, machine learning, and Internet of Things (IoT) are expected to further revolutionize the prototyping process. These innovations will enhance automation, improve predictive modelling, and allow for even quicker iterations.

Conclusion

The realm of rapid prototyping is an exciting frontier in manufacturing, and China is leading the charge. The combination of advanced technologies, skilled labor, and cost efficiency positions Chinese metal fabricators as ideal partners for businesses looking to accelerate their product development cycles. With deep knowledge and expertise, companies like Deep Mould exemplify the high standards and quality expected in the industry.

For businesses ready to take the next step in innovation, embracing China rapid prototyping is an opportunity not to be missed. By collaborating with expert partners, companies can transform their ideas into reality, paving the way for a successful future.